|

We specialize in high quality water jet machine

and other high pressure products

|

Portable CNC Waterjet Pipe Cutting Machines

Many times, there are needs to make cuts on pipes that are already installed

in fields, whether underground or elevated up in air. This requres to bring

the equipment of cutting to the site of jobs. In addition, waterjet is often the

preferred method of cutting because the materials flow in the pipes are flamble

or explosive. Therefore Portable Waterjet Machine emerged to the world.

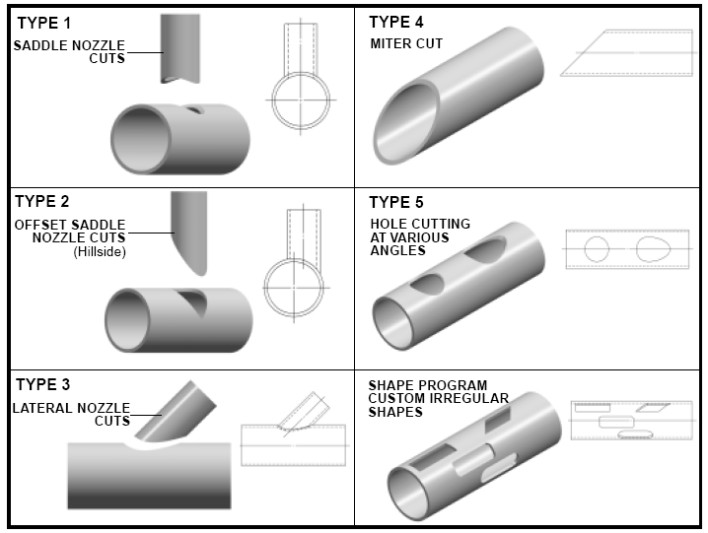

The cutting needs on these pipes are often as following: replacing damaged portion, adding new branch, etc.

For these applications, saddle cutts on the main pipe and fish mouth or miter cuts at the end of brach

pipes are the most common cuts. For accurate shape and size match of the saddle and fish mouth, CNC

controll is often used with portable waterjet cutting machine.

Saddle and fish mouth cut

Miter cut bend pipe

The portable water jet pipe cutting machine system consists of a high pressure water pump,

a CNC controlled rail system that carriers cutting head, and abrasie feeding system.

The waterjet pump is 30-50 hp and when cutting with abrasive, the max thickness of

mild steel is 80mm. The pump requires 3 phase electricity power supply of

220V -- 480V, 50 or 60 Hz, (specified by the customer). The pressurized water

is fed to the cutting head through a high pressure whip tubing.

The cutting rail can rotate around the pipe and the cutting head can travel along

the length of the rail. The CNC controller controls the rotation and the linear motion of the

cutting head along the rail simultaneously according to the CNC programming.

|

Advantage of IWM portable waterjet cutting machine.

IWM's special design of the portable waterjet cutting machine is espectially useful for the situations that pipe is not able to

move, and the only option is to let the waterejt cutting head go around the pipe to cut. There are two models of the portable

cutting head carrier. Model 1 is good for just cutting off the pipe. This vertion does not have CNC, and the cutting head

can just go around the pipe. Model 2 has a long rail and the cutting head can move along the rail while the rail goes

around the pipe. In this case the design has 2 axis, and it is capable to cut saddle and miter joints. Both models can cut

small and large diameters of pipes accourding to customers' requirements. The thickness of pipe that can be cut is up to

100mm.

Model 1: simple one axis, cuts around the pipe only.

|

|

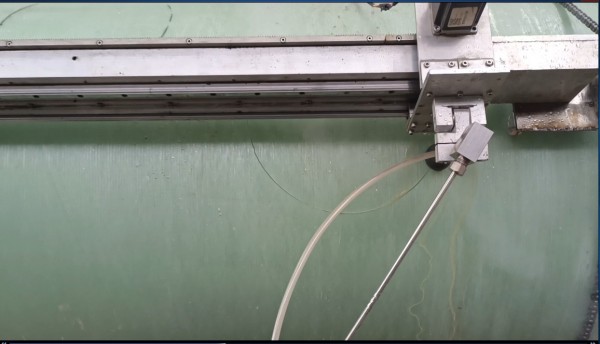

Model 2: two axis, long rail goes around the pipe and cutting head moves along the rail, can cut holes.

|

There are a few types of portable waterjet machines that are suitable for different cutting needs.

There are a few types of water jet pipe cutting machines that are suitable for different situations of pipes.

Here are some videos to show details of the portable waterjet pipe cutting machine, and to show the

actual cutting scenes.

Video 1: Model 1 portable waterjet cuts steel pipe.

Video 2: Model 2 portable waterjet cuts hole in GRP pipe.

Video 3: pipe cutting machine with chuck.

Perfect shape and size match from saddle and nozzle cut.

|

|

Zoom in to see the perfect combination of saddle and nose cut shape and size.

|

|

|